Keeping up to date with supplier technologies and meeting IPFL at Southern Manufacturing

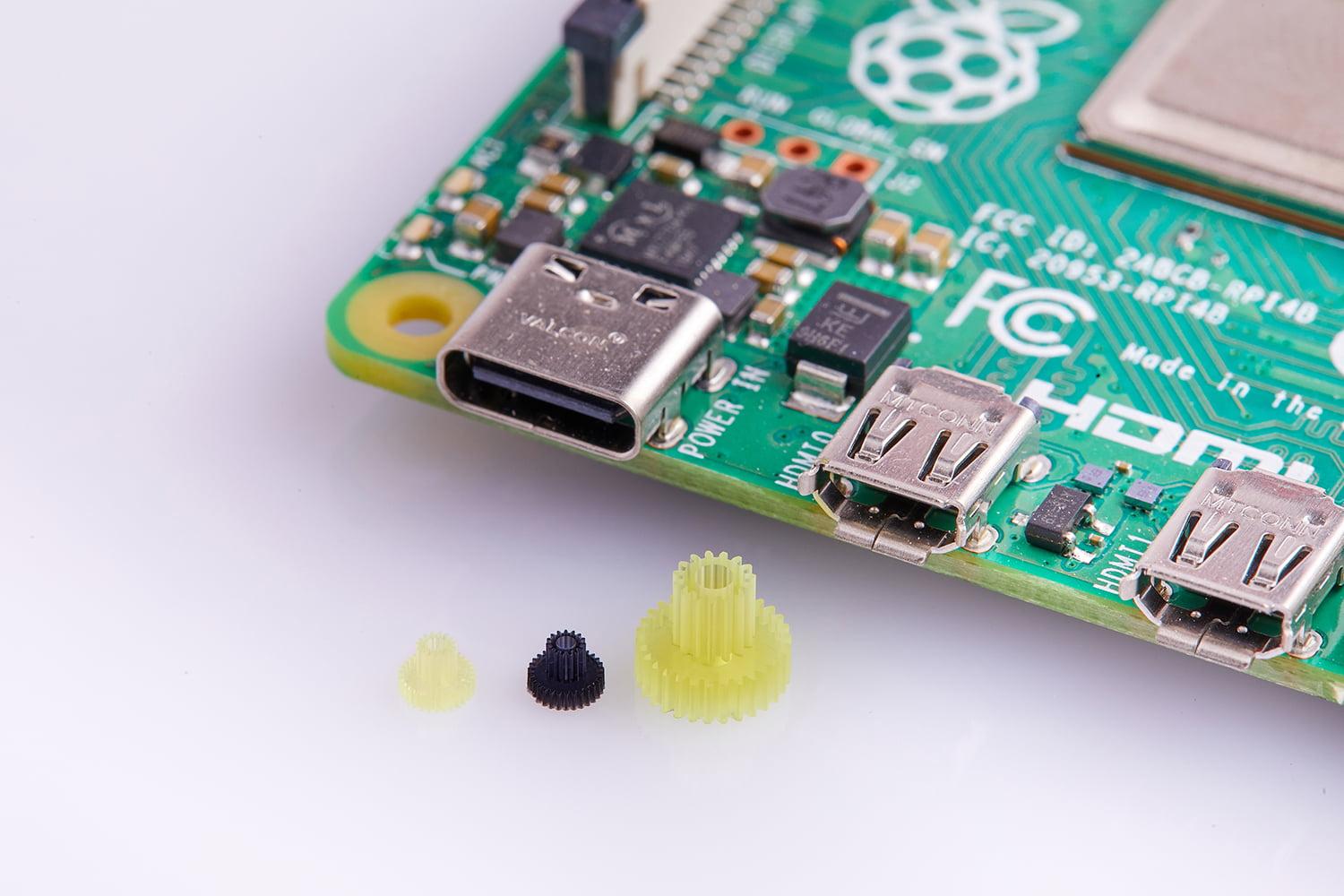

Yesterday Conficio Product Design attended the annual Southern Manufacturing show in Farnborough. It is a great opportunity to catch up with suppliers but also meet new ones too! This year we were impressed to see the advances made with 3D printing and how small the parts can be. We were particularly impressed with a company called IPFL who offer bespoke plastic parts, they had some 3D printed samples on the stand that were incredibly small using a technology we were unaware of called BMF projection micro SLA. If your project requires the need for some very small 3D printed parts go and check out there website below!

Website: https://www.ipfl.co.uk/

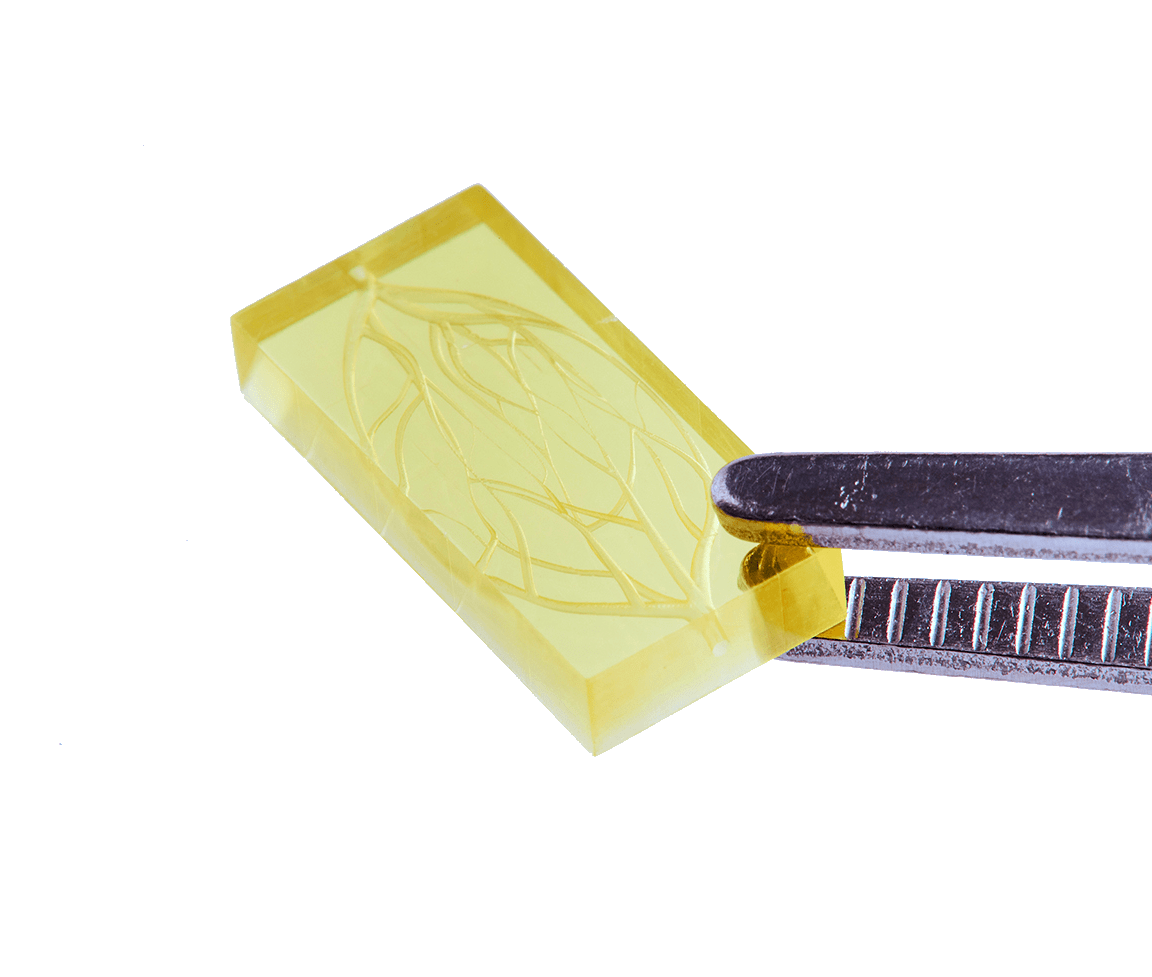

Projection Micro Stereolithography (PµSL) is a type of 3D printing technology that uses a UV light projector to cure a liquid photopolymer resin into a solid object. The resin is added to a tray, and the UV light projects the desired shape onto the resin. The light cures the resin and solidifies it, layer by layer. The process continues until the entire object has been built. PµSL is known for producing high-quality parts with a high level of detail and accuracy.

Its application spans microelectronics and medical devices such as delicately bespoke surgical stents or microfluidic channels for labs-on-a-chip devices. It can print at 10µm layers to achieve a surface polish of up to 0.4µm Ra on top surfaces and 1.5µm on sidewalls with a diverse material range including metals, plastics, and ceramics. Users can tailor the material to their application.

Ultra-High Resolution - Achieves resolutions up to 10 μm, making it one of the highest precision 3D printing technologies available.

Eco-Friendly Materials - Utilizes environmentally conscious resins, aligning with sustainability goals in manufacturing.

Microscale Manufacturing - Tailored for microscale applications, ensures consistent production of small-sized parts.

Diverse Industrial Applications - Ideal for sectors such as electronics, medical devices, microfluidics.

The 2μm series precision and versatility make them ideal for any industry requiring microscale parts with complex geometries and tight tolerances. With the introduction of the 2 micron printer, IPFL continues to expand the frontier of what’s possible in additive manufacturing.

// Meaning: From con- (“with, together”) + faciō (“do, make”).

// Verb: To make together, prepare, construct, produce, do thouroughly, complete, accomplish, finish, execute.

// Pronunciation: Con - fee - see - o

Conficio Product Design is a design consultancy based in Wilton, Wiltshire. Our team of engineers are dedicated to supporting both established corporations and small tech start-ups to develop exciting and bespoke products. Conficio will undertake the detailed components to your design whilst ensuring that your original idea is adhered to, we work with you to realise your goals. We require our clients to be invested in their design to ensure that we can Make Together.

At Conficio our team of multi-disciplined product design professionals are on hand to work closely with you to explore your concept and bring your idea to life.

© 2023 All Rights Reserved – Privacy Policy – Cookie Policy